Archive for May 2014

I'm using a MendelMax 1.5 and a Kossel alternative 3d printer. Both have their body made out of aluminium profiles, which i found out very useful and easy to handle. Profiles are straight, rigid and lightweight. My intention is to use them as the linear rails for the printers since they are also cheaper to chromium bars which i can't source easily in "normal" prices here in Greece.

I started using PLA for my tests, because i was already using the linear bushings ( http://www.thingiverse.com/thing:24990 ) and they were pretty good. I have no yet come to a conclusion about PLA guides on aluminium. I used them under my print-bed which weights more than 2kg and they wear off little by little on every print, leaving dust on the profiles.

Then, i tried to use some PTFE tubing on contact with the profile. At first i inserted the PTFE into the profile's channel. It seemed to work a bit, but the PTFE was also leaving some dust. Also the rectangular base had to touch the profile in order to stay in correct place. I thought also to use PTFE on top of the profile and not inside the channel, although i haven't found the correct tolerances.

Another approach was to use ABS with PTFE on my MMax's X-axis. The ABS was turning to dust far more easily and it was obvious that the carriage was not aligned any more due to the weight of the extruder. I tried another design with better balance but the outcome was the same.

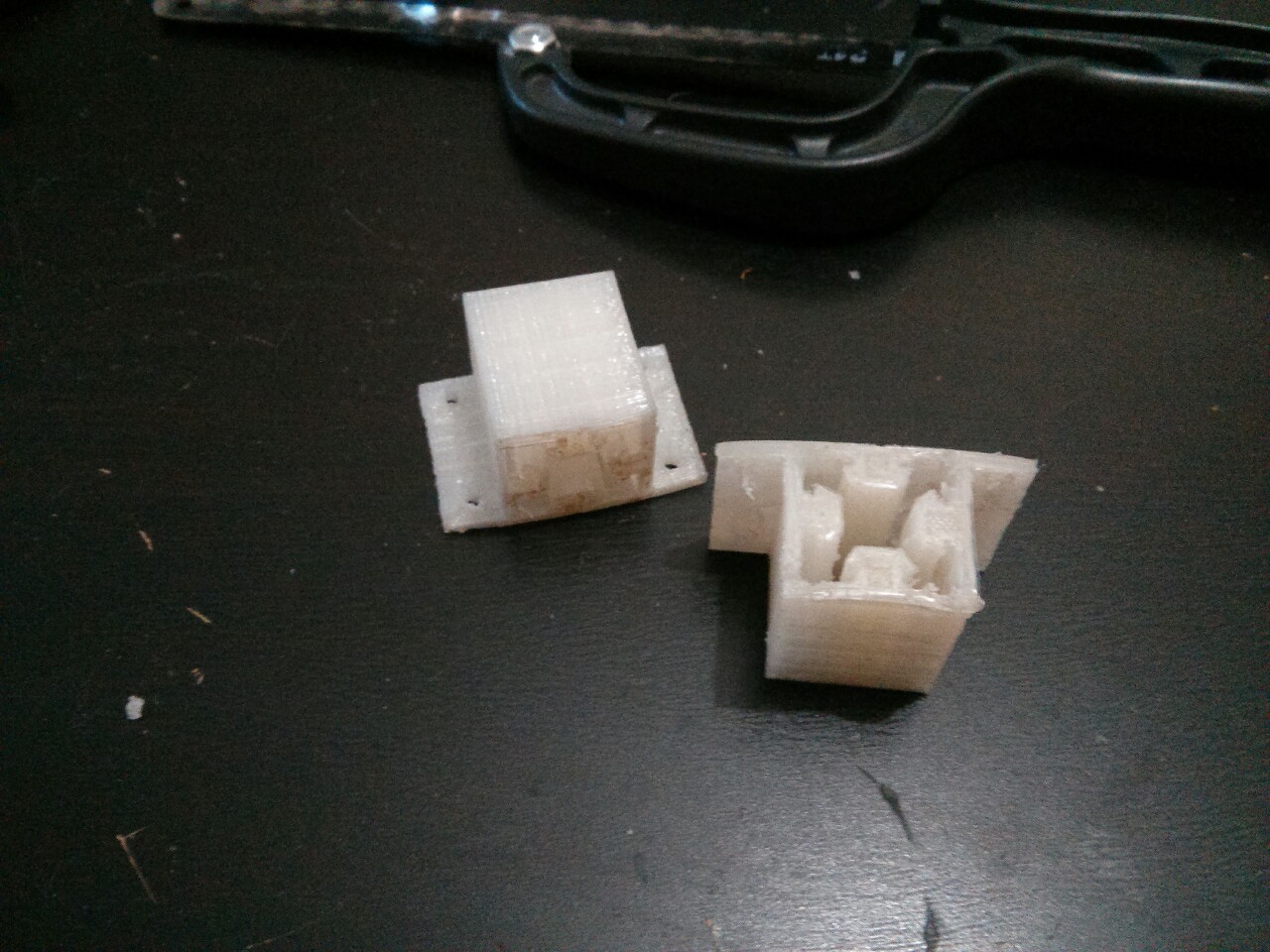

Lastly, i bought some nylon (Taulman 645) for another project, and thought to give it a try also. Although the tolerances again are not so good and the nylon "bushings" came out a bit tight, with some post-processing they fit nicely on the profiles. The good thing about nylon is that there are no visible wear on the profiles. No matter how many times i tried to roll them on the profile on order to get loose, they remain tight. As you can see, i cut one too and removed some plastic to test them. The nylon guide didn't wobble at all, even though the rectangular shape was broken.

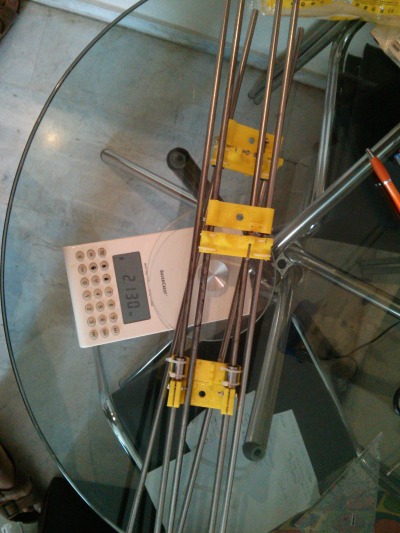

Removed 2.1kg from the delta printer, and from Kossel alt seems more like Kossel!

I am satisfied with their performance over the 0.5$ bushings and will let them on my delta until i buy some more nylon and find the correct tolerances for higher speeds.

Currently i printed this calibration test on my delta with the settings below:

Marlin settings:

Slic3r settings:

With some editing in the scad file already on thingiverse, you can get some working guides for your profiles. PLA is still in the game but i'll use it on lightweight applications.

I need to add some more detailed pictures.

I started using PLA for my tests, because i was already using the linear bushings ( http://www.thingiverse.com/thing:24990 ) and they were pretty good. I have no yet come to a conclusion about PLA guides on aluminium. I used them under my print-bed which weights more than 2kg and they wear off little by little on every print, leaving dust on the profiles.

Then, i tried to use some PTFE tubing on contact with the profile. At first i inserted the PTFE into the profile's channel. It seemed to work a bit, but the PTFE was also leaving some dust. Also the rectangular base had to touch the profile in order to stay in correct place. I thought also to use PTFE on top of the profile and not inside the channel, although i haven't found the correct tolerances.

Another approach was to use ABS with PTFE on my MMax's X-axis. The ABS was turning to dust far more easily and it was obvious that the carriage was not aligned any more due to the weight of the extruder. I tried another design with better balance but the outcome was the same.

Removed 2.1kg from the delta printer, and from Kossel alt seems more like Kossel!

I am satisfied with their performance over the 0.5$ bushings and will let them on my delta until i buy some more nylon and find the correct tolerances for higher speeds.

Currently i printed this calibration test on my delta with the settings below:

Marlin settings:

#define DEFAULT_MAX_ACCELERATION {6000,6000,6000,10000}

#define DEFAULT_ACCELERATION 3000 /

#define DEFAULT_RETRACT_ACCELERATION 3000

#define DEFAULT_XYJERK 19.0 // (mm/sec)

#define DEFAULT_ZJERK 19.0 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)

Slic3r settings:

perimeter_speed = 70

infill_speed = 100

travel_speed = 180

With some editing in the scad file already on thingiverse, you can get some working guides for your profiles. PLA is still in the game but i'll use it on lightweight applications.

I need to add some more detailed pictures.

http://cr3a7ure.tumblr.com/

Tumblr is easier to use with a smartphone than it is blogger..

Here i'll just sum up the actual "knowledge" obtained, but it's difficult to write a full post often.

Tumblr is easier to use with a smartphone than it is blogger..

Here i'll just sum up the actual "knowledge" obtained, but it's difficult to write a full post often.